Our PCB production is tailored for everything from prototype batches to medium-sized series. With our modern

surface-mount machine, we can handle all components available on the market. After assembly, the boards are soldered in

a hot air oven. All PCBs are inspected after soldering.

Our PCB production is tailored for everything from prototype batches to medium-sized series. With our modern

surface-mount machine, we can handle all components available on the market. After assembly, the boards are soldered in

a hot air oven. All PCBs are inspected after soldering.

All through-hole mounting is done manually, and the boards are soldered using lead-free wave soldering.

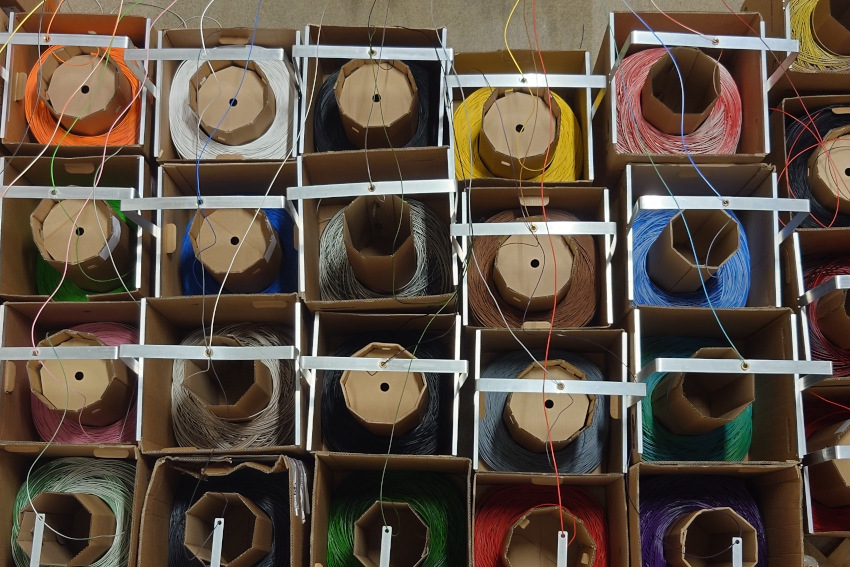

With advanced cable processing machines, we can manufacture cabling for your products efficiently and with high quality.

The cables are then tested using a computerized test system to eliminate miswiring.

With advanced cable processing machines, we can manufacture cabling for your products efficiently and with high quality.

The cables are then tested using a computerized test system to eliminate miswiring.

As a full-service provider, we offer to assemble PCBs, cabling, and enclosure components into a complete product — fully tailored to your specifications. We also handle small-scale enclosure processing in-house.